- Volume 60 , Number 2

- Page: 250–4

Modulan® grip-aids for leprosy patients

ABSTRACT

Made-to-measure Modulan® grip-aids were fitted to 755 articles for 155 patients with hand deformities due to leprosy. The acceptance of the grip-aids was, in general, good. No instance of contact dermatitis or skin irritation was reported. These grip-aids facilitated a normal grip with crippled hands, and thus considerably improved the quality of the patient's personal and working life. They increased the patient's self-esteem and self-confidence because he/she could handle everyday objects or tools without the help of others and could do his/her job-an important step toward social and economic rehabilitation.RÉSUMÉ

Des poignées de préhension Modulan® faites sur mesure ont été adaptées à 755 articles pour 155 patients présentant des déformités des mains ducs à la lèpre. L'acceptation des poignées fut bonne en général. Aucun cas de dermatite de contact ni d'irritation cutanée n'a été signalée. Ces poignées ont facilité une préhension normale avec des mains infirmes, et ont donc considérablement amélioré la qualité de la vie personnelle et professionnelle des patients. Elles ont augmenté le respect et la confiance en soi des patients, parce qu'il ou elle pouvait utiliser des objets ou outils de tous les jours sans l'aide d'autrui et pouvait réaliser son travail-un pas important vers la réhabilitation sociale et économique.RESUMEN

Se fabricaron, sobre medida, aditamentos Modulan® diseñados para manipular 755 artículos, y se instalaron en 155 pacientes con deformidades en las manos debidas a la lepra. La aceptación de estos aditamentos fue buena en general. No se reportaron casos de dermatitis por contacto o irritación de la piel. El uso de estos aditamentos facilitó el manejo de utensilios por los pacientes con deformidades en las manos y mejoró considerablemente su calidad de vida personal y laboral. Los aditamentos incrementaron la autoestima de los pacientes y la confianza en sí mismos porque ahora pudieron manipular objetos o herramientas de uso rutinario sin la ayuda de otros indivíduos y porque pudicron realizar su trabajo-un paso importante hacia su rehabilitación social y económica.It is estimated that approximately 25% of the leprosy patients who are not treated at an early stage of the disease develop anesthesia and/or deformities of the hands and feet [Lechat, M. F. Future strategies of leprosy control (handout, page 3). First International Leprosy Symposium in Guangzhou, People's Republic of China, November 1985]. The deformity rate varies from country to country [(1, 3, 7) and Sehgal, V. N. and Srivastava, G. HD deformities and disabilities: current status. The Star 47 (1988) 10-13]. The mobile claw hand is, in general, the most commonly seen deformity in patients with leprosy, and accounted for 13% of all the deformities found in Maiduguri in Nigeria (3). Patients with deformities of the hand have difficulty in holding articles of daily use. This makes everyday life difficult and any sort of job often impossible. Made-to-measure Modulan® grip-aids to help such handicapped patients have recently been developed by Ciba-Geigy Limited, Basle, Switzerland, in technical cooperation with the Training and Research in the Appropriate Disability-Design Unit of the City of London Polytechnic.

MATERIALS AND METHODS

Materials

These grip-aids are made from a twocomponent (AV 1580 GB/HV 1580 GB) epoxy resin putty with a shelf-life of at least 1 year. The yellow putty contains the diglycidyl ether of bisphenol A (DGEBPA) as the synthetic epoxy resin. It is nontoxic and its acute oral LD50 in rats is > 10,000 nig/kg. A study demonstrated the absence of tumor induction by DGEBPA when applied to the skin of CF1 mice for 2 years at subirritant concentrations of 1% or 10% (9). There is no evidence that occupational exposure to DGEBPA-type epoxy resins results in cytogenic damage (5) or presents a carcinogenic hazard to the skin or other organs (4). Repetitive skin and eye irritation tests in rabbits did not reveal any irritant effect of the epoxy resin. However, its skin-sensitizing potential was detected in the contact allergenicity test in guinea pigs. The blue putty contains 4% free trimethyl hexamethylene diamine (TMD) as the hardener. It is an aliphatic amine polyamine and is slightly alkaline.

Method for preparing Modulan® grip-aids

1. Examine the deformity and plan the grip-aid: First assess the deformity and plan the finished grip-aid in your mind. The article must be thoroughly cleaned, preferably with alcohol (spirit), to remove oil and grease. The wooden handles should be scraped if oil or grease has penetrated into the wood (2).

2. Start: Put on gloves to avoid skin irritation. Estimate the quantity of each Modulan® component you need for the gripaid. With separate spatulas remove from the tins equal amounts of Modulan® yellow and Modulan® blue, and roll the Modulan® yellow and Modulan® blue material separately into two equal-sized balls.

3. Mix and examine: Mix the Modulan® yellow and Modulan® blue together between the palms of the hands thoroughly so that a homogeneous, uniformly green putty is formed.

4. Mould: Fit the Modulan® green onto the prepared item and mould into the rough shape of the grip-aid. The Modulan® green remains soft for about 20 min and must be moulded within this time. To avoid skin irritation, ask the user to apply the protective cream.

5. Fit: Place the item on which Modulan® green has been applied in the hand of the user and ask him/her to grasp it as if he/she were actually using it. The user must not squeeze the Modulan® too tightly or too lightly. While the patient is holding the gripaid, the displaced putty is pressed by the technician into all corners and gaps between the fingers and the article so that the area of contact is increased and suitable stops for the fingers are provided.

6. Remove: Lift the fingers gently, one by one, and carefully remove the hand so that the grip-aid is not distorted. Ask the patient to wash his/her hands with soap and water. Round off all edges and sharp corners, without disturbing any indentations produced by the patient's grip.

7. Keep in a safe place: Place the Modulan® grip-aid in such a way that the moulding will not be distorted. Although after 2 hours the Modulan® will be hard and the article can be taken home, it will be ready for use only after about a 12-hour curing time. Once set, the grip-aid can be filed to remove sharp edges or to slightly reshape it. Minor alterations can also be made by sand-papering.

8. Explain to the patient: Patient education is a vital factor. The importance of grasping the grip-aid properly should be explained to the patient. Because of the anesthesia, leprosy patients tend to use too much pressure while grasping the grip-aid. This can be prevented by educating the patient to hold the tool in a more relaxed way. Patients should be instructed to come for follow-ups at regular intervals.

Numbers of patients and grip-aids

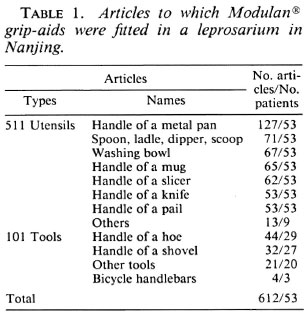

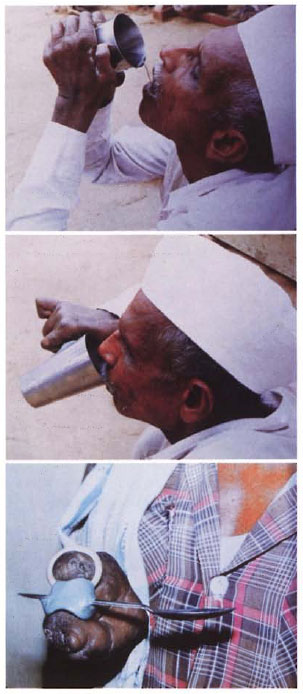

Field tests were conducted by the City of London Polytechnic in 1988 mainly at the Bombay Leprosy Project, Bombay, India. Eighty-six Modulan® grip-aids and two splints were made for 69 patients with deformities of the hand due to leprosy. In 1989-1990, 612 Modulan® grip-aids were made in a leprosarium in Nanjing, People's Rupublic of China, for various articles for 53 patients (40 male and 13 female) with deformities of the hands due to leprosy (Table 1).

In 1989-1990, 57 Modulan® grip-aids were made for 33 patients (21 male, 12 female) under the Comprehensive Leprosy Care Project in 22 villages of Borsad Taluka in Gujarat, India. In this project Mr. Kingsley, a physiotherapist from the Bombay Leprosy Project trained in making Modulan® grip-aids, spent a day with the patient to observe his/her actual daily life and take notes on his/her handicaps and difficulties. The next day, grip-aids were fitted to the articles which included spoons, chapatti rollers, drinking glasses, pens, walking sticks, cooking vessels, grass cutters and axes.

RESULTS

Grip-aids were fitted to 755 articles for 155 patients. Skin irritation was not reported by any of the patients nor by paramedical or medical personnel, and the acceptance of grip-aids was in general very good. No patient complained of blisters due to either heat transfer or friction. The gripaid broke in three cases. Five patients did not use the articles to which the grip-aids were fitted.

Grip-aids could be fitted to all tools and utensils used in daily life, except to those with a greasy surface. The time taken to prepare grip-aids was 5-10 minutes for spoons, pens, mugs and knife grips, and about 15 minutes for tool-grips. Grip-aids did not shrink and were washable and durable. They were resistant to shock and acids.

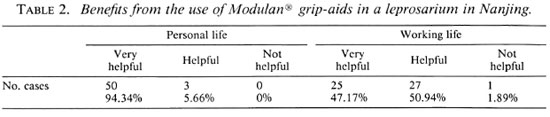

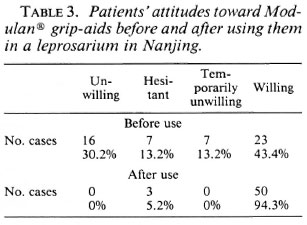

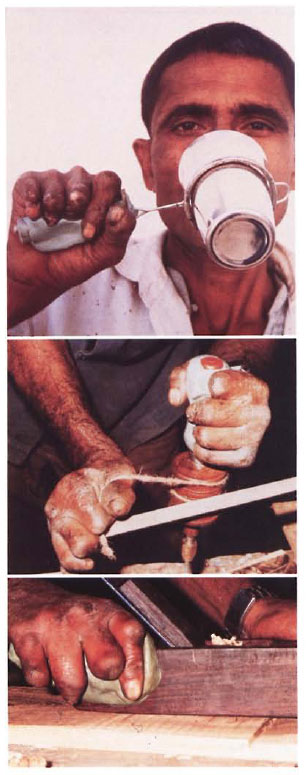

Grip-aids moulded by the user's handgrip resulted in the even distribution of force during their use. They facilitated a normal grip with crippled hands and thus improved considerably the quality of the patient's personal and working life (Tables 2, 3). For example, an Indian farmer at the Comprehensive Leprosy Care Project in Gujarat, India, with deformed hands could not drink water by taking a tumbler to his lips. He used to half-fill the tumbler with water and pour it into his mouth from a distance (Fig. 1). When a grip-aid was fitted to one side of the tumbler and a handle made from a disposable plastic syringe he could resume his normal way of drinking water (Fig. 2). Another patient in the same project had hardly any stumps at the metacarpophalangeal joints and only a very small thumb web. Therefore, he could not hold a spoon steady although the grip-aid had been fitted to it. In this case, a loop was formed for additional support by passing an insulated wire through the grip aid. (Fig. 3). The patient was very happy since he could then use the grip-aid for eating without spilling food on his clothes.

Fig. 1. Patient with deformed hands pouring water into his mouth from a distance.

Fig. 2. Same patient now drinking water in a normal way after grip-aid was fitted to tumbler.

Fig. 3. Modulan 5 grip-aid, with an additional loop support made of insulated wire, for a patient with severe deformity of the hand.

In most cases, grip-aids made the handling of articles much easier for leprosy patients with deformed hands. They increased the patients' self-esteem and self-confidence because they could handle everyday objects (Fig. 4) or tools without the help of others and could do their job-an important step toward social and economic rehabilitation (Figs. 5 and 6).

Fig. 4. Patient drinking water in a normal way after grip-aid was fitted to a holder on tumbler.

Fig. 5. Carpenter with deformed hands using a drill to which a Modulan® grip-aid has been fitted.

Fig. 6. Carpenter with a deformed hand working with a plane to which a Modulan 5 grip-aid has been fitted.

DISCUSSION

The beneficial effects of grip-aids moulded from an epoxy resin putty in 25 leprosy patients were reported first from India by Ganapati, et al. in 1983 (2). Modulan® putty is better in consistency and color, and is more stable than the putty used previously by Ganapati, et al.

Studies performed so far have shown the usefulness, good tolerability and practicability of made-to-measure Modulan® gripaids for leprosy patients. Microcellular rubber can be incorporated onto Modulan® grip-aids to make them lighter and to afford more protection to the hand. Modulan® grip-aids facilitate a normal grip with deformed hands. Abrasions due to an unnaturally fierce grip and injuries due to the slipping of the hand are prevented. The use of a plane with a grip-aid can prevent the hand from slipping against the blade (Fig. 6). The moulding can be made to suit the individual deformity exactly, so that a grip is possible even where digits are missing. The Modulan® grip-aid is a much easier way of helping the patient ergonomically than modifying the design of the tools used for work and everyday life.

Modulan® grip-aids are indicated in: 1) Disability in everyday life due to an inability to grasp objects properly following primary and/or secondary hand deformities due to leprosy. 2) Functional handicap following partial or total claw hand due to leprosy for an ergonomic benefit in the patient's occupation involving the use of tools which have to be grasped firmly. 3) Partial or total loss of fingers/thumb, particularly if bilateral, compelling the patient to use only both palms to grasp objects. 4) Insensitive hand with good muscle power, since the indentations and ridges of the grip-aid prevent the objects from slipping out of the hand, and distribute the pressure more evenly. 5) Patients with long-standing, irreversible claw deformity and old age, which rule out surgery, e.g., arthrodesis of proximal interphalangeal joint, but who still require functional help by external aids. 6) Patients with damage to the extensor expansion at the proximal interphalangeal joint level, p.i.p. joint deformity ("hooding deformity") with volar capsule contracture associated with, or without palmar skin contracture who may not benefit from surgery. 7) Thumbwe b contracture in total (ulnar and median) claw hand with limited opening for "key pinch." 8) Mobile claw hand where facilities for surgery are not available or when the patient is not willing to undergo surgical correction.

Modulan® grip-aids are not indicated in progressive myopathic disorders and when skin rash, abrasions, blisters and/or ulcers are seen on the deformed hand.

Studies performed to date have shown that Modulan® grip-aids can be of great help in improving the quality of the personal and working life of leprosy patients with deformities of the hands and, thus, can help them get a fresh grip on life and facilitate their reintegration into the community.

Acknowledgment. The authors are grateful to Dr. B. Arora, Ms. P. Commons, Dr. D. Gisbcrtz, Ms. P. Grewal, Mrs. K. Guha, Dr. He Daxun, Dr. J.-P. Heiniger, Mr. S. Kingslcy, Mr. D. Karamat, Mr. I. Paul, Mr. J. P. Purdew and Mrs. Westmacott for their contribution to the Modulan® grip-aids project, and to Mrs. Neela Shah for providing excellent photographs.

REFERENCES

1. CHATURVEDI, R. M. and KARTIKEYAN, S. Employment status of leprosy patients with deformities in a suburban slum. Indian J. Lepr. 62(1990)109-112.

2. GANAPATI, R., CASTON, D., REGO, D. J., BODKHE, L. D. and KULKARNI, D. R. Epoxy resin mouldings as aids for leprosy patients with deformities. Rehab. Asia 24(1983)19-25.

3. IYERE, B. B. Leprosy deformities: experience in Molai Leprosy Hospital, Maiduguri, Nigeria. Lepr. Rev. 61(1990)171-179.

4. MANSON, M. M. Epoxides-is there a human health problem? Br. J. Ind. Med. 37(1980)317-336 (181 réf.).

5. MITELMAN, F., FREGERT, S., HEDNER, K. and HILL-BERTZ-NILSSON, K. Occupational exposure to epoxy resins has no cytogenetic effect. Mutat. Res. 77(1980)345-348.

6. NOORDEEN, S. K. A look at world leprosy. Lepr. Rev. 62(1991)72-86.

7. REDDY, N. B. B., SATPATHY, S. K., KRISHNAN, S. A. R. and SRINIVASAN, T. Social aspects of leprosy. Lepr. Rev. 56(1985)23-25.

8. THANGARAJ, R. H. and YAWALKAR, S. J. Leprosy for Medical Practitioners and Paramedical Workers. 4th edn. Basle: CIBA-GEIGY Limited, 1989.

9. ZAKOVA, N., ZAK, F., FROEHLICH, E. and HESS, R. Evaluation of skin carcinogenicity of technical 2, 2-bis-(p-glycidyloxyphenyl)-propanein CF1 mice. Food Chem. Toxicol. 23(1985)1081-1089.

1. M.D., D.V.D., Dermatologist and Leprologist; Ciba-Geigy Limited, Basle, Switzerland.

2. Pharmaceuticals Division, Ciba-Geigy Limited, Basle, Switzerland.

3. M. S., Project Director, Comprehensive Leprosy Care Project in Borsad and Plastic Surgeon at J. J. Hospital, Bombay, India.

4. M.B.B.S., D.D.V., Director, Bombay Leprosy Project, Bombay, India.

5. M.D.; Chinese Academy of Medical Sciences, Nanjing, People's Republic of China.

6. M.D., Institute of Dermatology, Chinese Academy of Medical Sciences, Nanjing, People's Republic of China.

7. M.D., Nanjing Leprosarium, Nanjing, People's Republic of China.

8. Director, Training and Research in Appropriate Disability Design Unit, City of London Polytechnic, London, U.K.

Received for publication on 29 August 1991.

Accepted for publication in revised form on 22 January 1991.